Industrial Filters

Microporous structure of PTFE membrane and surface filtration method applied

Longer filter life due to increased dust filtration ratio and pulsing/dedusting frequency

Energy consumption and operational and maintenance costs reduced

Used in a wide range of fields such as thermal power plants, steel mills, incinerators, cement plants, etc.

New Product Certificate

Performance Certificate

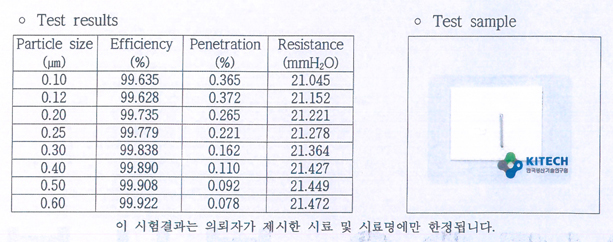

Test Result & Test Sample

Strengths

-

01

Localization Certification

100% localization of filter material

Acquired new product certifications (NEPs)

Performance certification (EPC)

Supplied to 5 KEPCO power generation companies (2013 to present) -

02

High Performance

Reduced hazardous material leakage compared to the MB (melt-blown, in-depth filtration) filter

Surface filtration method, Excellent pulsing performance (more than 13 times) -

03

Customized Production

Applicable to various environmental conditions due to functional coating (antistatic, flame retardant, etc.)

Reduced costs by custom-manufacture to demand such as specifications

Technical Data

The person in charge

- Jake Lee

- Sales

+82 61-902-4075

+82 61-902-4075 sales@komemtec.com

sales@komemtec.com- CONTACT